High pressure thick wall alloy elbow

Professional management of various materials of stainless steel, pipes, steel pipes, steel, profiles, hardware and electrical materials, etc., widely used in petroleum, petrochemical, pharmaceutical, electric power, chemical, gas, heating, metallurgy and other industries.

- Commodity name: High pressure thick wall alloy elbow

- Commodity ID: 1083670429043412992

- Product Description

-

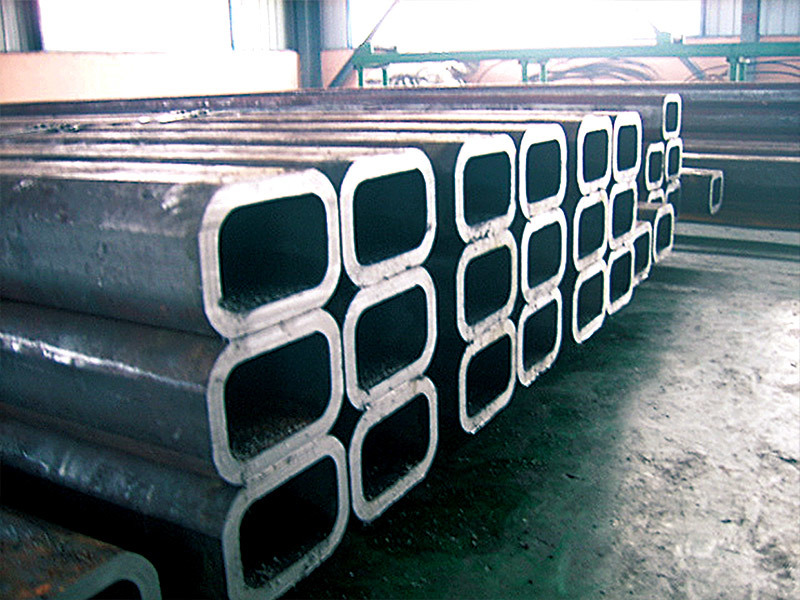

High pressure thick wall alloy elbow

Our company specializes in various materials of stainless steel, alloy steel and carbon steel pressure pipe fittings, pressure pipe flanges, metal hoses, soft connections, wear-resistant pipes, anti-corrosion pipes, thermal insulation pipes, supports and hangers, and cable bridges for conveying machinery; Sales of various materials of stainless steel, alloy steel and high temperature resistant, high pressure steel pipes, steel materials, profiles, hardware and electrical materials of special materials. The company has always been based on the principle of quality first, reasonable price, customer first, considerate service, giving customers profits, small profits but quick turnover, and honesty and trustworthiness as its purpose. Over the years, our company has established a stable supply system and a good sales system with users. Our company's products have been widely used in petroleum, petrochemical, pharmaceutical, electric power, chemical, gas, heating, metallurgy and other industries.

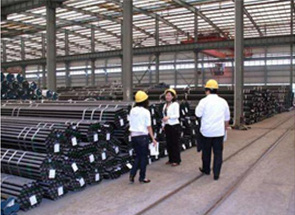

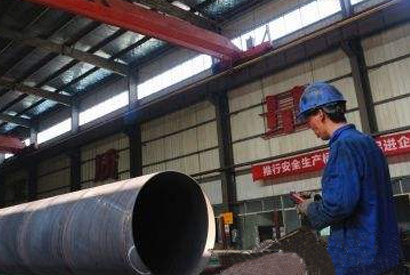

Production Workshop

The company attaches great importance to product quality, and strictly controls everything from raw materials entering the factory to re-inspection. It has self-inspection capabilities for chemical analysis, performance testing, non-destructive testing and other inspection items of materials, ensuring the correctness and rigor of product process links.

|

|

|

|

|

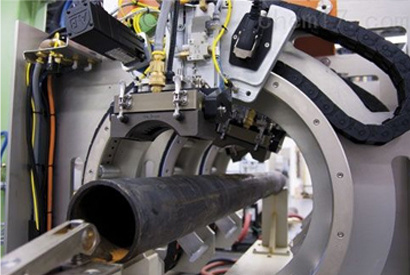

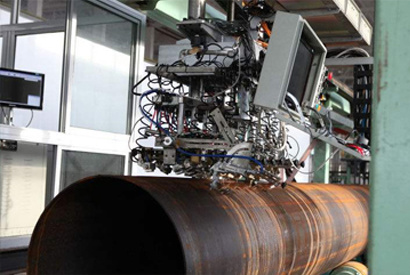

Non-destructive Testing

We pass standard specifications, inspection work content and requirements, and control of non-conforming products. Metal forming performance test: stamping forming performance test, metal upsetting test, metal pipe process performance test, steel hardenability test, welding performance test, chemical composition test, macro/microstructure test and fracture analysis and other testing methods. Strictly control the quality and control the quality of product output.

|

|

|

|

|

|

Get a Quote

Note: Please leave your contact information, our professionals will contact you as soon as possible!