SY/T 0413-2002 Technical standard for polyethylene anti-corrosion coating of buried steel track

SY/T 0413-2002 Technical Standard for Polyethylene Anti-corrosion Coating of Buried Steel Pipeline Economic benefits, this standard is specially formulated. This standard applies to the design, production and construction acceptance of extruded polyethylene anti-corrosion coatings for buried steel pipelines. The extruded polyethylene anti-corrosion coating can be divided into normal temperature type (N) whose long-term working temperature does not exceed 50°C and high-temperature type (H) whose long-term working temperature does not exceed 70°C. The design, production and construction acceptance of extruded polyethylene anti-corrosion coatings for buried steel pipelines shall not only comply with the provisions of this standard, but also comply with the relevant current national mandatory standards.

GB/T 23257-2009 Polyethylene anti-corrosion coating for buried steel pipelines

This standard specifies the minimum technical requirements for extruded polyethylene anti-corrosion coatings for buried steel pipelines. This standard applies to the design, production and construction acceptance of extruded polyethylene anti-corrosion coatings for buried steel pipelines. Extruded polyethylene anti-corrosion layer across the pipeline can be implemented by reference. The extruded polyethylene anti-corrosion coating can be divided into normal temperature type (N) whose maximum long-term working temperature does not exceed 50°C and high-temperature type (H) whose long-term maximum working temperature does not exceed 70°C.

Divided into ordinary grade enhanced grade anti-corrosion thickness 1.8-3.7um

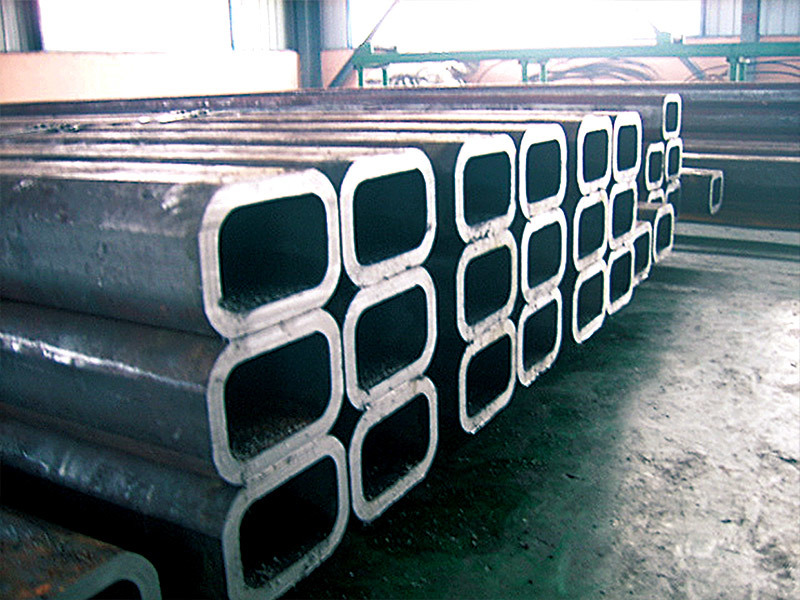

Anti-corrosion steel pipe refers to steel pipes that have been processed by anti-corrosion technology, which can effectively prevent or slow down the corrosion phenomenon caused by chemical or electrochemical reactions during transportation and use. However, we still don’t know all kinds of anti-corrosion steel pipe anti-corrosion methods and processes. For 2PE/3PE anti-corrosion, 2PP/3PP anti-corrosion, buried fire-fighting pipeline anti-corrosion, steel-plastic composite pipe anti-corrosion, underground pipeline reinforced anti-corrosion, epoxy coal anti-corrosion Steel pipe anti-corrosion, PE anti-corrosion steel pipe anti-corrosion and several common anti-corrosion are introduced.

1. 2PE/3PE anti-corrosion method:

The bottom layer of the three-layer PE is epoxy paint, the middle layer is polymer adhesive, and the surface layer is polyolefin. Adhesives can use modified polyolefins, which contain polar groups grafted to the main chain of polyolefin carbon bonds. In this way, the adhesive can not only blend with the surface unmodified polyolefin, but also use the polar group to react with the epoxy resin. This combination is characterized by optimum bond strength between the three coatings, while the properties and characteristics of the individual layers complement each other. It is characterized by high cost and complicated process.

The first layer of epoxy powder (FBE>100um) (epoxy powder >100um refers to greater than 100 microns)

The second layer of adhesive (AD) 170~250um

The third layer of polyethylene (PE) is 2.5-3.7mm. The three materials are integrated and firmly combined with the steel pipe to form an excellent anti-corrosion layer.

The 3PE anti-corrosion layer organically combines the anti-corrosion performance of fusion-bonded epoxy powder with the mechanical scratch protection performance of polyethylene, and at the same time solves the market problem of polyethylene. Due to the poor adhesion of the hot melt adhesive, the peeled polyethylene has a shielding effect on cathodic protection. The 3PE anti-corrosion layer has high requirements on the surface treatment state of the pipe, and the depth of the anchor pattern should reach 50 μm to 75 μm, otherwise it will affect the ability of the anti-cathode stripping and waterproof penetration of the anti-corrosion layer.

The materials used for pipeline anti-corrosion are directly related to the quality of pipeline anti-corrosion. Therefore, when anti-corrosion is carried out, the raw materials must pass the test. Different anti-corrosion materials require different raw materials.

1. The main raw materials used in 3PE anticorrosion are polyethylene and polypropylene.

2. Epoxy resin anticorrosion mainly uses epoxy resin composite material coating, phenolic epoxy coating and polymer composite material.

3. Epoxy coal tar pitch anticorrosion mainly uses asphalt anticorrosion paint and polypropylene non-woven fabric.

4. Cement mortar is mainly suitable for cement mortar anticorrosion.

5. Cold wrapping tape refers to the adhesive tape used for anti-corrosion winding. Cold wrapping tape generally includes polyethylene (composite) type anti-corrosion tape, polypropylene reinforced fiber anti-corrosion tape, aluminum foil anti-ultraviolet anti-corrosion tape, polyethylene 660 type (modified) Asphalt) tape, double-sided adhesive anti-corrosion inner tape (this tape is rarely used in China, but it is very practical and widely used abroad, and is generally used for export) and epoxy coal tar anti-corrosion tape. The implementation standards are SY/T 0414-98 and SY/T0447-96.

6. Heat shrinkable tape is generally used for jointing of anti-corrosion steel pipes

It is designed for the anti-corrosion of buried and overhead steel pipe welds and the insulation repair of heat-insulated pipes. It is composed of radiation cross-linked polyolefin substrate and special sealing hot melt adhesive. The special sealing hot melt adhesive can form a good bond with polyolefin substrate, steel pipe surface and solid epoxy coating.

The characteristics of cold-wound tape and 3PE heat-shrinkable tape are: it is suitable for the main anti-corrosion layer pipes of various materials, while other methods are suitable for the main anti-corrosion layer pipes of the same or similar materials.

In the production of flanges, it is necessary to frequently contact various drawings, and use views, sectional views, and sectional views to show the internal and external structure of the flange; the outline size and transformation of each part. Reading drawings is the basic requirement of flange manufacturers for employees.

General methods and steps for reading flange drawings:

(1) First look at the title bar to get an overview of the parts

Look at the title bar to understand the name, material and proportion of the part, so as to understand the function of the part in general, and judge which type of part the part belongs to from the name. Judging the approximate processing method of the part from the material. Judging the actual size of the part from the ratio, so as to have a preliminary understanding of the part.

(2) Analyze the research view and imagine the shape of the structure

Look at the view, analyze the configuration of each view of the part and the relationship between the views, the expression method and content of the expression, use the drawing method of the combination, the shape analysis method and the line surface analysis method to understand the structure of each part of the part, Imagine the shape, relative position and function of each part of the part.

(3) Analyze all sizes and clarify size requirements

Comprehensively analyze the view and shape, analyze the dimensional benchmarks in the three directions of length, width and height of the part, then start from the benchmark, take the structural shape analysis as a clue, and then understand the shaping and positioning dimensions of each shape, and clarify the role of each size, graphics The dimension and dimension express the shape and size of the part. When reading the drawing, the view, dimension and shape structure should be combined and analyzed.

(4) Analyze technical requirements and comprehensively understand the whole picture

When reading the drawing, you should clarify the technical requirements such as surface roughness, dimensional tolerance, and shape tolerance. Understand the meaning of its code name. If necessary, contact the parts related to the part to analyze together.