Construction method of steel support

Release Time:

2023-03-10

Before the excavation of the foundation pit, a sufficient number of steel pipe supports, flexible heads, brackets, wire ropes and other materials should be prepared on site. After the steel pipe support enters the site, the quality of the steel pipe should be carefully checked in strict accordance with the design requirements and relevant normative standards, and unqualified support materials are strictly prohibited from being put into use. Steel pipe support: φ609 welded steel pipe with a wall thickness of 16mm. Both ends are connected by steel flanges with a diameter of 750mm.

1. Construction preparations

Before the excavation of the foundation pit, a sufficient number of steel pipe supports, flexible heads, brackets, wire ropes and other materials should be prepared on site. After the steel pipe support enters the site, the quality of the steel pipe should be carefully checked in strict accordance with the design requirements and relevant normative standards, and unqualified support materials are strictly prohibited from being put into use.

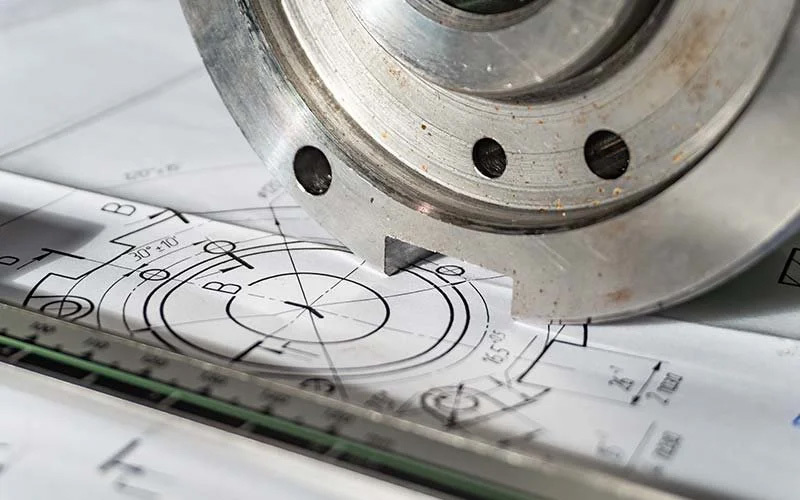

Steel pipe support: φ609 welded steel pipe with a wall thickness of 16mm. Both ends are connected by steel flanges with a diameter of 750mm.

Steel Purlins: Steel purlins are made of double-node 40 I-beams.

Steel wedge: the material is manganese steel, the thickness is 2cm, 4cm, 6cm, 8cm, 10cm.

High-strength bolts: M24 hexagon head high-strength bolts are used, and the screw length is 10cm.

2. Support installation

1) steel pipe support assembly

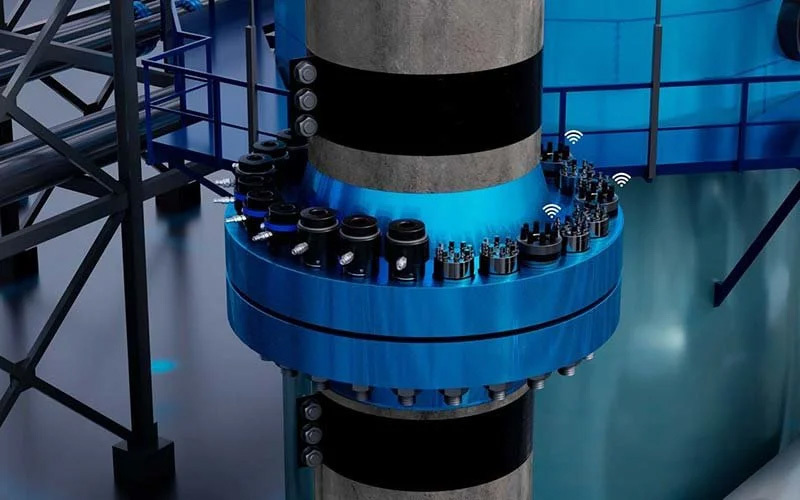

Since the construction site is relatively small, in order to reduce the unsupported exposure time of the foundation pit and shorten the construction time of each support cycle, when the steel support is erected: the steel support should be pre-assembled outside the foundation pit first, and checked with the width of the foundation pit Finally, disassemble and hoist the assembled steel bracket into the foundation pit in sections, and then install it vertically after the assembly in the foundation pit is completed.

Supporting steel pipe connection: use high-strength bolts to connect supporting steel pipes. When bolted connections are used, symmetrical force is required to prevent the eccentricity of the steel pipe support.

2) Measurement line, support positioning

When the soil is excavated to 30cm below the bottom of the steel support, immediately organize full-time personnel to measure, arrange and position the support according to the design drawings. The allowable deviation requirements for bracket positioning are: 2cm (horizontal position deviation), 1.5cm (height deviation). Mark the installation height and horizontal position of the steel bracket with red paint.

3) Cut out the ground wall reinforcement at the position of the support beam, and weld the support beam

After checking the elevation plane position of the steel bracket, in order to facilitate the positioning and fixing of the bracket, a rack device should be installed on the wall and the walls on both sides of the foundation pit. The shelf device is welded with a 2cm thick triangular steel plate on the main reinforcement of the ground wall. Two supporting beams are arranged at both ends of each steel bracket, and the effective welding length of the triangular steel plate and the main reinforcement of the ground wall is not less than 25cm.

4) Secondary protection and anti-drop reinforcement after the steel support is erected

In order to prevent the steel bracket from falling due to various reasons after the installation is completed, secondary protection and reinforcement to prevent falling should be added at both ends of the steel bracket. Use 20cm-long expansion bolts and 1cm-thick steel plates to make lifting lugs, and drive them into the ground wall to fix them. The suspension point is set 1 meter directly above the steel support. Then fasten both ends of the steel bracket with φ14mm steel wire rope, and connect it to the angle steel lug.

Label:

Relevant Information