What kind of problems exist in processing stainless steel flanges and how to solve them?

Release Time:

2023-03-10

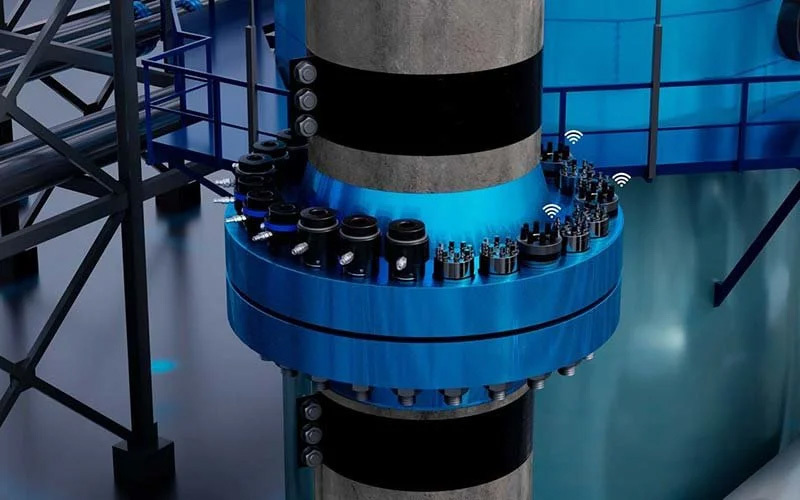

Weld defects: The weld defects of stainless steel flanges are serious. If manual mechanical grinding is used to make up for it, the resulting grinding marks will cause uneven surfaces and affect the appearance; uneven passivation of grinding and polishing: manual grinding and polishing After pickling and passivation treatment, it is difficult to achieve a uniform and consistent treatment effect for workpieces with large areas, and it is impossible to obtain an ideal uniform surface. It also has the disadvantages of working hours and high cost of auxiliary materials;

Weld defects: The weld defects of stainless steel flanges are serious. If manual mechanical grinding is used to make up for it, the resulting grinding marks will cause uneven surfaces and affect the appearance; uneven passivation of grinding and polishing: manual grinding and polishing After pickling and passivation treatment, it is difficult to achieve a uniform and consistent treatment effect for workpieces with large areas, and it is impossible to obtain an ideal uniform surface. It also has the disadvantages of working hours and high cost of auxiliary materials;

Scratches are difficult to remove: overall pickling passivation, chemical corrosion or electrochemical corrosion will occur in the presence of corrosive media to rust, and carbon steel and spatters adhered to the surface of stainless steel due to scratches and welding spatters cannot be removed. other impurities;

How to solve the problem of stainless steel flange processing?

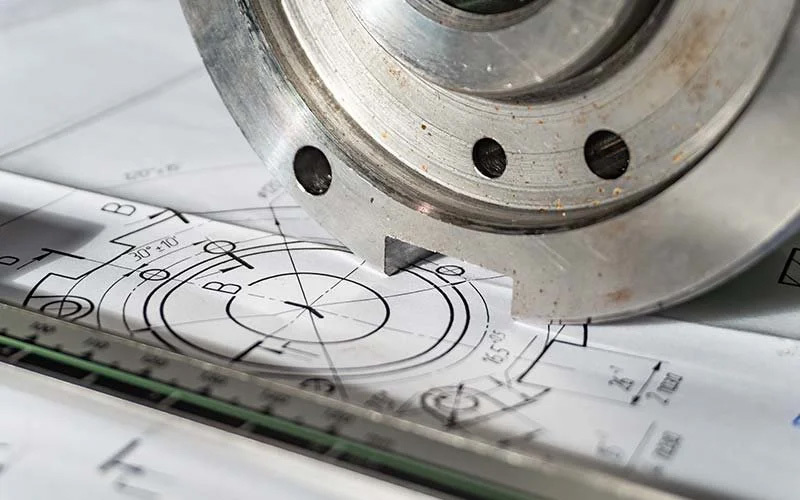

1. Select blanking. After completion, enter the next process. Different stainless steel workpieces enter the corresponding process according to the processing requirements;

2. When bending, first of all, according to the size on the drawing, the thickness of the stainless steel 304 seamless steel pipe material should be used to determine the tool and sipe used for bending. Avoiding the deformation caused by the collision between the product and the tool is the key to the selection of the upper mold (at the same time In a product, different types of upper molds may be used), and the selection of the lower mold is determined according to the thickness of the plate.

3. In order to weld firmly, put bumps on the workpiece to be welded, so that the bumps can be in uniform contact with the flat plate before energized welding, so as to ensure consistent heating of each point, and at the same time determine the welding position, which needs to be welded. Good preloading time, pressure holding time, maintenance time, rest time, to ensure that the workpiece can be spot welded firmly.

Label:

Relevant Information